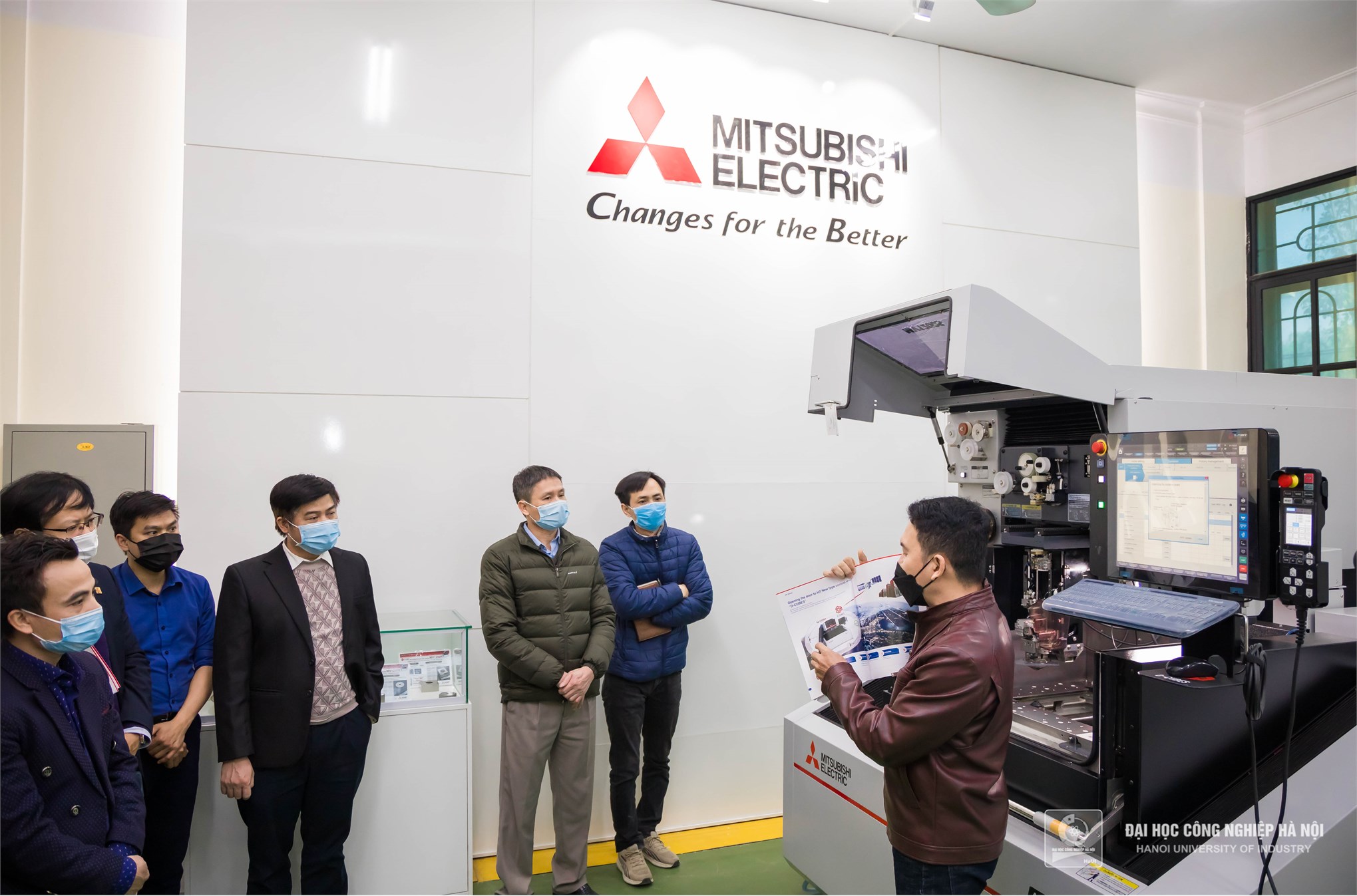

Mitsubishi Electric Vietnam handed over wire-cut EDM to HaUI

On the morning of January 18, 2022, Mitsubishi Electric Vietnam proceeded with the Handover Ceremony of wire-cut EDM equipment to the Vietnam Japan Center - Hanoi University of Industry.

Attending the Handover ceremony, representing Mitsubishi Electric Vietnam, there were Mr. Umeto - General Director, Mr. Shin Lida - Technical Director, and Mr. Yoichi Matsufuji - Deputy Technical Director. On HaUI's side, there were r. Bui Thi Ngan - Vice-Rector, representatives of leaders of units: Vietnam Japan Center, Center for Mechanical Engineering, HaUI - Foxconn Center for Technical Training, Center for Enterprise Partnership, Faculty of Mechanical Engineering.

Speaking at the event, Mr. Umeto congratulated HaUI on its development in recent years. He affirmed: “Mitsubishi Electric Vietnam decides to sponsor the wire-cut EDM for HaUI because of its reputation as a prestigious higher education institution along with its commitment in leading in innovation and investing in modern equipment and technology to support student learning.” He hoped that closer cooperation between the two parties would improve the teaching quality of HaUI.

On behalf of the Hanoi University of Industry, Dr. Bui Thi Ngan reviewed the cooperation process between Mitsubishi Electric Vietnam and the university. The Vice-Rector also hoped that the bond between the company and HaUI in general, and Vietnam Japan Center in particular, would continue to develop more and more strongly. Dr. Bui Thi Ngan expressed her gratitude to Mitsubishi Electric for always accompanying HaUI.

Overview of the wire-cut EDM:

Model name: MV1200S

Machining accuracy & Stability

Next-generation drive system and optimum machine structure

* Equipped with a linear shaft motor(LSM)

* Circular accuracy within 1μ is realized using an optical drive system(ODS).

Automatic wire threading

Advanced technologies for greatly improved productivity

* New annealing system greatly improves wire threading with a curl ratio of less than 10%.

* Wire breakpoint insertion is greatly improved for thick workpieces.

* Wire threading suitable for workpiece shape. (jet on/off and submerged breakpoint insertion)

Productivity

Advanced Productivity

* Surface roughness improvements are realized through enhanced power supply performance for high-speed machining.

* Surface finish reduced by 50% by machining with only 2 cuts.

* Machining time comparison for Rz 3.5 μm/Ra 0.45 μm with 3 cuts.

Operability

Excellent performance with "Easy operation", "human error reduction" and "connect ability" supporting productivity improvement for customers.

* Information is displayed on a large 19-inch screen.

* Functions to be viewed or used are called by one touch from the HOME screen.

* The number of operations performed on the Navigation menu from setup to machining is reduced by almost 40%. (as compared to the past)

* Setup performance is improved by a thin hand pendant box with LED.