Successfully researched, designed and manufactured PVD vacuum coating equipment for supporting industry

With the desire to improve the quality and service life of supporting industrial products, the research team including Assoc.Prof.Dr. Pham Duc Cuong and MSc. Nguyen Duc Luan - HaUI Institute of Technology, Hanoi University of Industry has successfully researched, designed and manufactured PVD vacuum coating equipment.

In the field of mechanical engineering in general and the supporting industry in particular, hard coatings created by the method of physical deposition in a vacuum environment (Physical Vapor Deposition - PVD) are increasingly being applied. The advantages of PVD coatings are that they are glossy, more corrosion resistant and increase the hardness of metal products. PVD coating colors are very diverse such as yellow, copper, blue, black... Especially, this advanced coating method is very safe, non-polluting, non-toxic.

Assoc.Prof.Dr. Pham Duc Cuong - Director of HaUI Institute of Technology, Hanoi University of Industry - core member of the research team

In Vietnam, PVD vacuum coating technology has been researched and gradually applied by a number of universities and research institutes. Many scientific and technological projects at all levels on PVD coating technology have been carried out. However, so far, these projects have only focused on researching the coating technology of some traditional coatings such as TiN, CrN on the basis of using imported and long-life coating equipment, and control systems still use old technology.

Hanoi University of Industry is one of the pioneers in Vietnam to research and apply PVD coating technology. The University has invested in a laboratory with the UNIVEX400 coating system and a number of equipment to measure coating characteristics. PVD-HCM 700 is a hard coating film forming equipment manufactured and integrated in the project "Research, design and manufacture of film coating equipment using PVD technology, applied to products in the supporting industry to improve their quality and longevity” under the Supporting Industry program 2019 - 2020 chaired by Hanoi University of Industry.

The PVD-HCM 700 coating equipment

The PVD-HCM 700 coating equipment

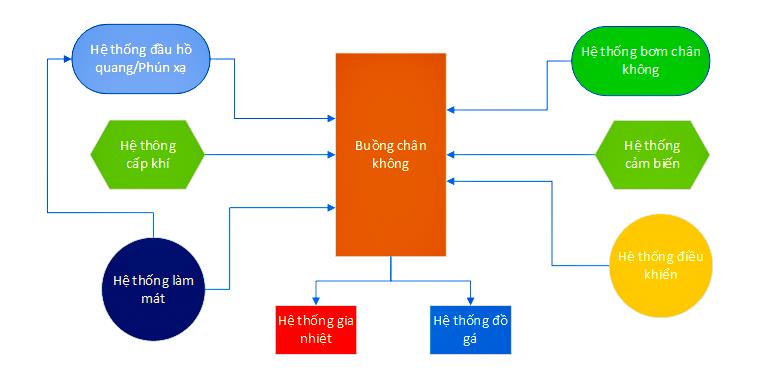

The PVD-HCM 700 uses both sputtering and vacuum arc technology, with a chamber size of 700x700mm. The device can arrange 02 sputtering heads with a capacity of 15kW/head, or 4 arc heads with a capacity of 10kW/head, or combine 1 sputtering head and 2 arc heads for different coating processes. The integration of both coating techniques allows flexible adjustment during the study as it is possible to use each technique separately or use both techniques for a coating.

This feature is very useful because coatings created by different techniques will have different characteristics and scope of application. In particular, coatings created by integrating both techniques can have outstanding properties in terms of hardness or structure. Due to the integration of both techniques on one system of equipment, the control and software system are individually designed in modules, allowing the use of each technique independently or a combination of both in the same process.

The diagram of principles of functional modules of the HCM-700 PVD coating equipment

On the basis of referring to the characteristics and capabilities of the UNIVEX400 and DREVA 400 coating systems, the research team analyzed and set out general technical requirements for the design, manufacture and integration coating system as follows:

- Be able to use 2 techniques: Magnetic and arc sputtering;

- Have larger vacuum chamber size, internal fixture system allows coating samples or batches with suitable dimensions;

- Technology clusters supporting the coating process: heating, creating bias voltage, sensors, gas supply

- The control system with software is stable, highly automatic, simple and flexible to operate; having the ability to upgrade hardware and software respectively…

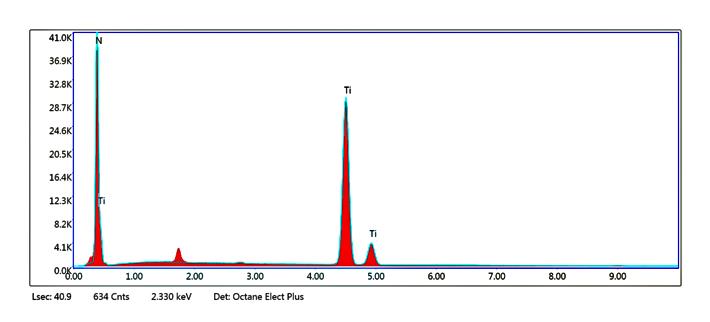

Analysis results of the evaluative composition of the sample after coating TiN with sputtering (left)

and arc (right)

Test results of TiN coating on a number of cutting tools and products show that TiN coating on steel base made by both techniques achieves properties equivalent to those of commercialized and published coatings in the world: hardness 2100 - 2300 Hv, Ti:N ratio is valid (49:51), the thickness can be controlled to reach 3.0 - 3.5mm. Initial results show that the coating is successfully created on the surface of the product and is not peeled off during the machining process.

The initial results have proved the technological mastery of the research team of HaUI Institute of Technology, Hanoi University of Industry in designing, manufacturing and integrating the vacuum coating system by PVD method and applying to a number of product areas serving the supporting industry.

Pictures of some products coated with TiN by PVD-HCM 700 coating equipment

It can be said that this is the first PVD coating system built in Vietnam that is capable of meeting requirements for both research and trial production with 2 different techniques, reaching and exceeding the design specifications in terms of capacity and scale.

The successful fabrication of PVD vacuum coating equipment will be an important premise for the research team to continue the research on equipment and technology to create hard coatings by physical deposition method in a perfect vacuum and expand the scope of applications in the future.

-

Monday, 10:31 20/12/2021