Success in Research on Automatic Mooncake Production Line

Getting 90.8 points, the group of 5 students from the Faculty of Mechanical Engineering including Bui Trong Cuong, Vu Lai Cong Huyen, Pham Van Long, Do Duc Hai and Nguyen Xuan Truong excellently won the First Prize in the Scientific Research Contest for Students with the idea of simulating an automatic mooncake production line.

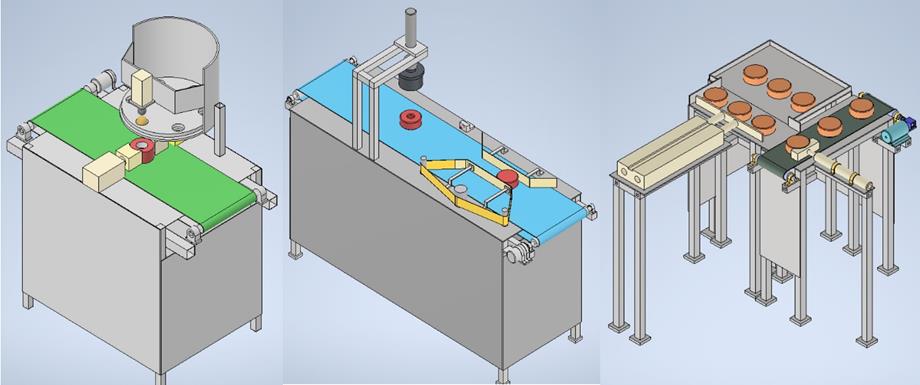

Figure 1: Conceptual model of machine clusters in the production line

The research team shared: Due to technical backwardness and the lack of engineers and workers makes our country's traditional cake manufacturing industry no longer have the flourishing as it was. That requires factories and companies to have a vision and come up with effective solutions.

The group has researched on the automatic production line to get ideas and determine the parameters from which to design the first drawings for the line, then the 2D machine design, to 3D line drawing and simulate the operation of the mooncake production line. However, due to many limitations in the process of researching, there are still errors but they can be orientation and reference for further studies.

The line consists of 4 main machines, each machine performs a different job. The line is designed to be able to move by wheels with brakes to ensure the closest distance between the two machines. The brake mechanism will help the machine secure its position during operation.

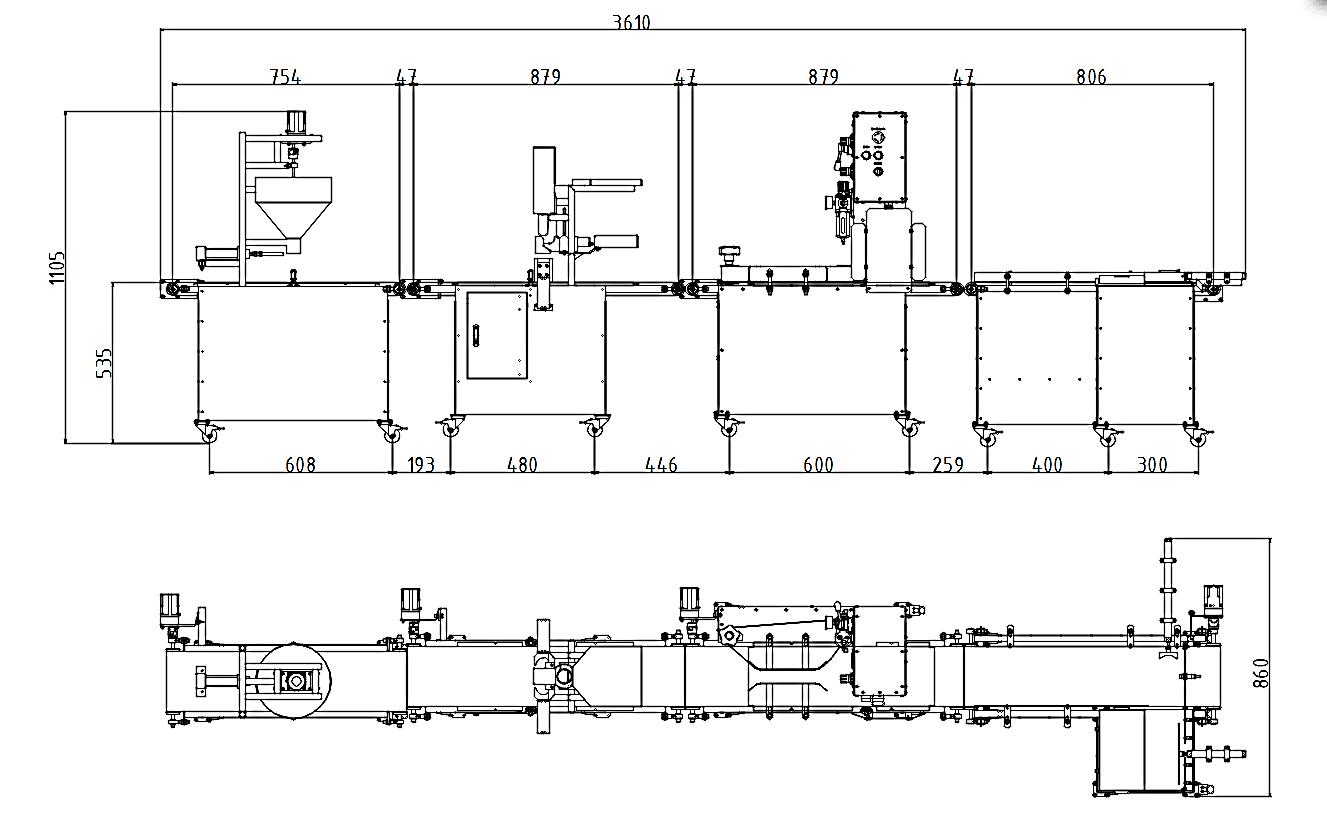

- Total size of the line:

+ Height: 1105 mm

+ Length: 3610 mm

+ Width: 860 mm

Figure 2: The overview size of the line

Figure 2: The overview size of the line

Powder dividing mechanism: using a powder hopper, the powder is put into the large end of the hopper. The powder is extruded to the small end of the hopper by means of a mechanism using a screw conveyor. The screw conveyor is connected to the strong motor with large torque by means of a coupling. The motor of screw conveyor runs at a fixed speed to ensure that the powder is evenly compressed and extruded.

The powder extruded from the storage hopper has a circular cylinder shape, meeting the required diameter size. From there, for each size of cake selected for production, we will get parameters to input into the sensor. The multiplier sensor helps the dough cutting cylinder to work, the powder to be cut falls to the conveyor and to the next operation.

Filling adding mechanism: The dough divided from machine 1 is passed to machine 2 by means of a load. When the controller receives a signal from the clamping cylinder sensor, the two clamping arms simultaneously translates the dough clamp. Next, the hole-making cylinder works, right after that, the filling will be pushed from the container to fall into the hole created on the cake shell. Completing the clamping cylinder cycle opens up the filled dough to continue moving on the conveyor belt to the next process.

Forming mechanism: The filled dough in process 3 will be run through a vertical conveyor, with the aim of rounding. The purpose is to lose the hollow air in the cake, narrow the mouth of the cake, and reduce the diameter of the cake.

Shape the cake using a cylinder that transmits pressure to the cake mold to squeeze the filled dough into the desired shape and size. The mechanism that presses the cake into the right shape is then supplied with air to the mold that pushes the shaped cake back to the conveyor. The forming process is more optimized with the fact that the forming plates can be changed to diversify the product; just by changing the press plate, there are many different designs.

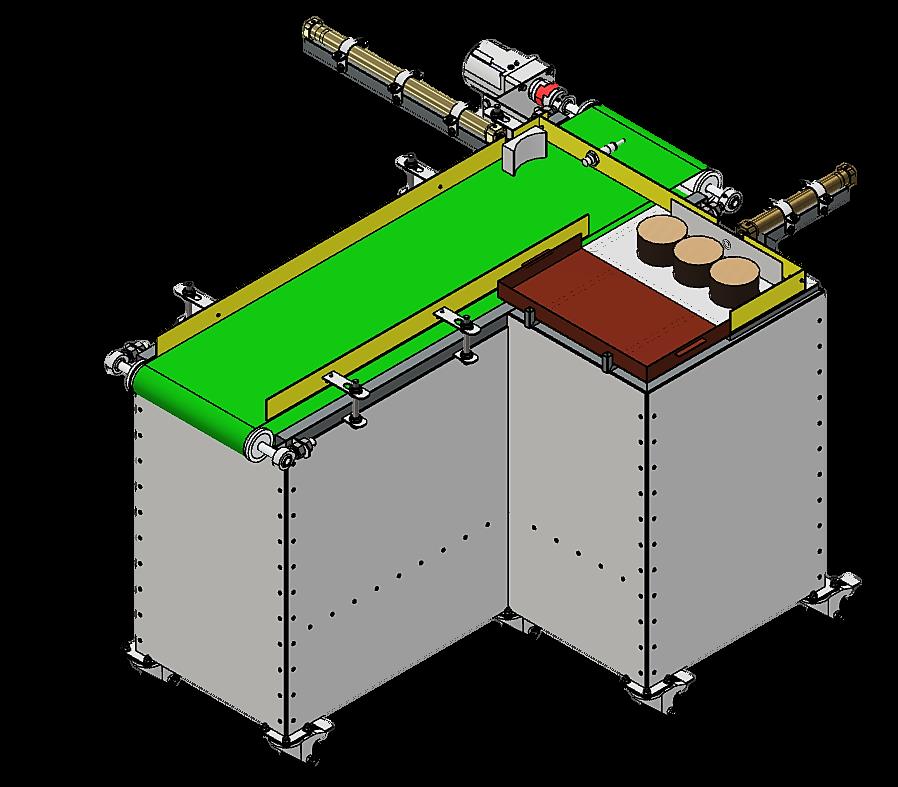

Figure 3: Moon cake stacking machine

Putting the cake into the tray: The products from conveyor 3 will be moved on to conveyor 4. From ensuring the position after the cake forming step, the cakes will be moved to the sensor position. After sensor 1 detects that cylinder 1 pushes the shaped cakes into the right position, the counter counts all 3 cakes, then they will be pushed into the container thanks to cylinder 2.

The mechanisms in the machine are selected with high standard, helping to increase the accuracy. Along with that, the time to receive the sensor signal or the size of the details are calculated in accordance with the machine structure.

Simulation of automatic mooncake making line

Nguyen Xuan Truong (2nd from the right) on behalf of the research team received the Certificate of Merit at the Conference for Summarizing and Awarding Students in Scientific Research.

Nguyen Xuan Truong (2nd from the right) on behalf of the research team received the Certificate of Merit at the Conference for Summarizing and Awarding Students in Scientific Research.

The research paper was highly appreciated by the Council. The team has basically completed the design, the machine operation structure and selected the appropriate standard details for the production line. They have also calculated the design of the cake production line, and learnt more about NX and PLC software to simulate the operation of the line, thereby bringing the design closer to reality