Students in Mold Engineering Technology: Ready to Integrate into the Global Supply Chain

With the goal of training a highly skilled workforce for the Mold Engineering Technology industry, the School of Mechanical and Automotive Engineering, Hanoi University of Industry (HaUI) has expanded its partnerships, innovating and enhancing the quality of education. Close collaboration with Korean partners, one of the world’s leading manufacturing nations, has opened up attractive job opportunities, allowing HaUI students to confidently participate in the global supply chain.

Addressing the Demand for Skilled Labor

With a sharp vision towards the development trends in the Mold Engineering industry, in 2020, the School of Mechanical and Automotive Engineering at HaUI pioneered the launch of the Mold Engineering Technology program, becoming the first institution in Vietnam to offer specialized training in this field.

First Mold Engineering Graduates in 2024

After four years, HaUI has successfully met the urgent needs of the labor market by training a high-quality workforce with in-depth knowledge in mold design and manufacturing. These students are proficient in using advanced mold design software such as SolidWorks, AutoCAD, CATIA, NX, and are capable of applying international standards in managing and optimizing production processes. Notably, the first cohort of students secured jobs immediately after graduation, with attractive salaries at both domestic and foreign direct investment (FDI) companies.

Achieving the training goals relies heavily on the collaboration between the university and businesses. This close partnership has created an ideal learning, research, and practical environment for Mold Engineering Technology students. Thanks to equipment sponsored by projects like JiCa (Japan) and Foxconn (Taiwan), students have the opportunity to work with the most advanced production machinery and equipment.

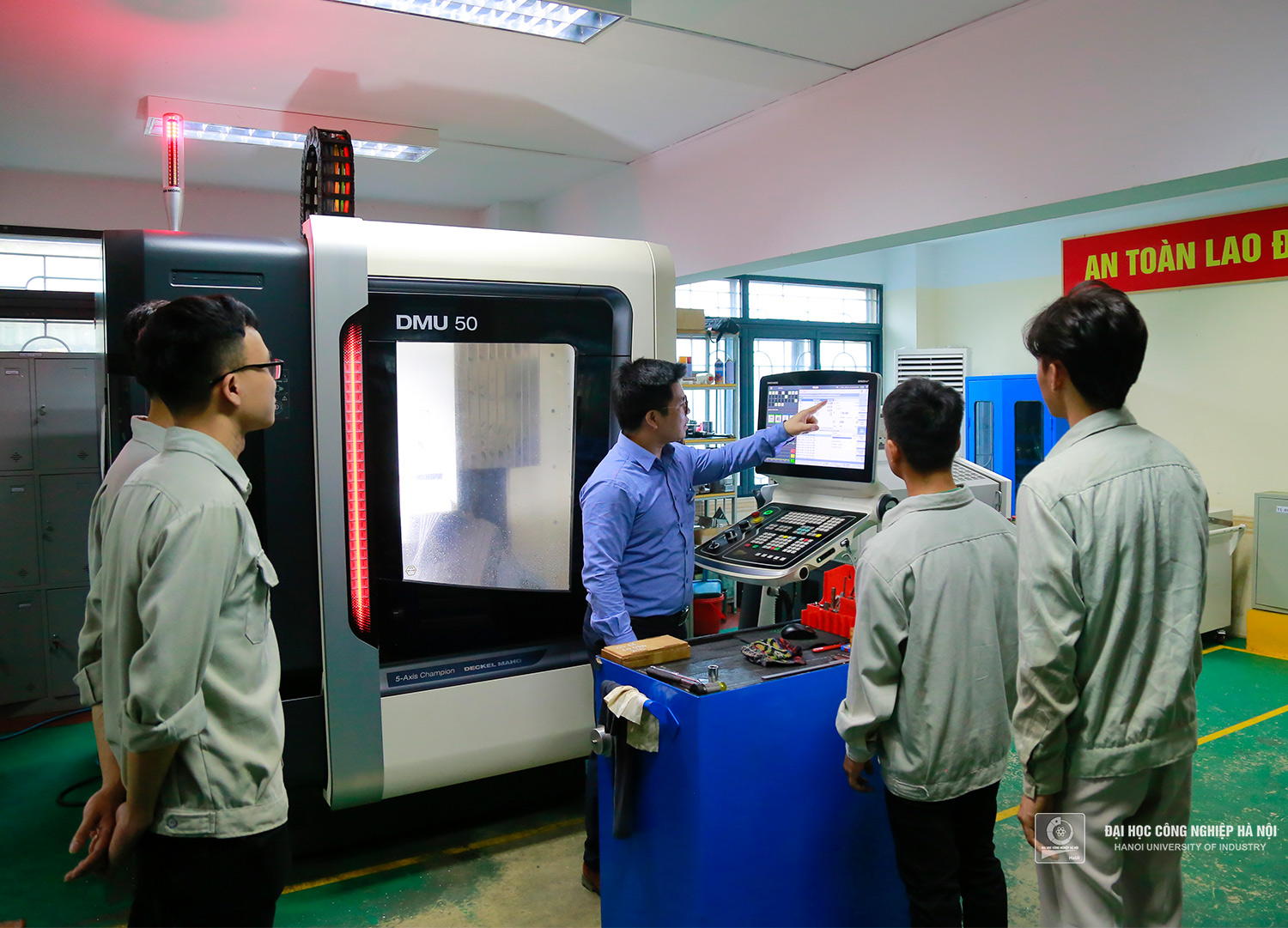

Students practice with a 5-axis CNC machining machine

Students practice with a 5-axis CNC machining machine

Lecturers guide students in operating the SE180EV-A plastic injection molding machine from Sumitomo, Japan

Renishaw EQUATOR 300 automated gauge from the USA

Students design and program mold machining using CAD/CAM software

Students design and program mold machining using CAD/CAM software

Students participated in an experiential visit at the company

Building the Future through Innovation

In addition to academic learning, students are exposed to real-world experiences through company visits, specialized seminars, and opportunities to participate in practical research projects alongside industry experts. These experiences help students apply their acquired knowledge in real-world contexts and confidently integrate into professional work environments upon graduation. In fact, many students were recruited by companies during their final project defenses.

The represetatives of Cosmos Co., Ltd. participated in the defense session of graduation projects for the Mold Engineering Technology program

As one of the strategic partners of the Mold Engineering Technology sector, the representative of Cosmos Co., Ltd. expressed satisfaction and was impressed with the graduation projects of students from the School of Mechanical and Automotive Engineering. The students’ creative ideas and ability to solve complex, technically demanding problems, requiring high precision from the design stage to manufacturing, demonstrate that they are fully prepared to enter a professional working environment. Their success is a clear testament to the effective collaboration between the university and businesses, forming a closed-loop training system that eliminates the need for retraining by companies after graduation.

With the knowledge and skills accumulated over four years of study at the Faculty of Mechanical Engineering and Automotive Technology, the first generation of students from the Mold Engineering Technology program promises to be a key force contributing to the rise of Vietnam's mold industry on the international stage.

International Integration

As education continues to internationalize and global integration deepens, Assoc. Prof. Dr. Hoang Tien Dung, Principal of School of Mechanical and Automotive Engineering at HaUI, emphasized that the university aims to "export" its training products to countries with strong industrial sectors such as South Korea, Japan, China, and Taiwan. This is part of a broader strategy to enhance HaUI’s global standing.

Assoc. Prof. Dr. Hoang Tien Dung – Principal of the School of Mechanical and Automotive Engineering

One key advantage in this process is that several of the university’s staff have participated in specialized research and training in South Korea, serving as advisors for mold engineering competitions.

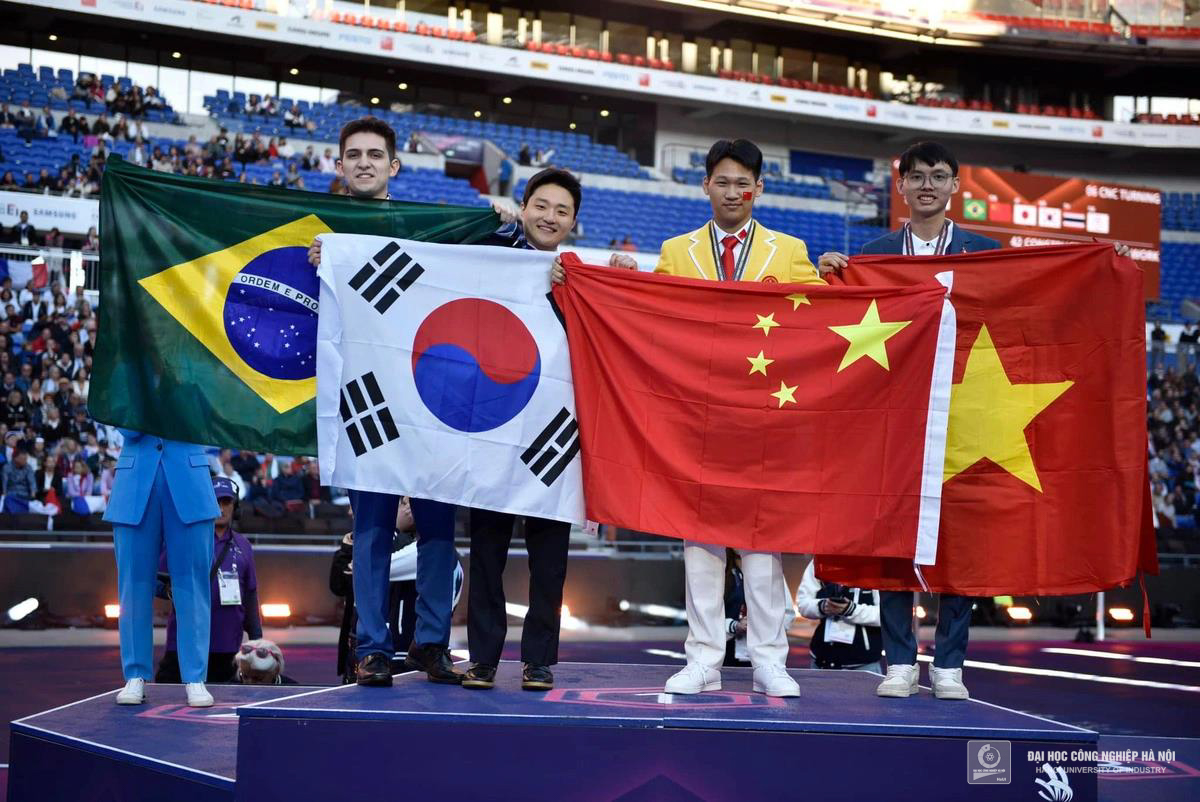

HaUI students achieved outstanding results in the WorldSkills Competition

Students from the Mold Engineering Technology program won the Special Prize at the International Olympiad on Extrusion

In recent years, the entrance scores for the Mold Engineering Technology program have increased, with many applicants holding IELTS scores of 7.0 or higher. Additionally, HaUI encourages students to participate in international technical competitions like the WorldSkills Competition and the International Olympiad in Extrusion. These provide valuable opportunities for students to learn from strong competitors from developed countries and establish themselves on the global stage.

Hanoi University of Industry signed a Memorandum of Understanding (MoU) for collaboration with the Korea Skilled Engineer Association

Strengthening International Partnerships

International cooperation, particularly with South Korea - a leading global manufacturing country - remains a key focus in the university’s training strategy. HaUI has signed memorandums of understanding with the Korean Skilled Engineers Association, inviting numerous experts to teach and organize specialized scientific and technological seminars.

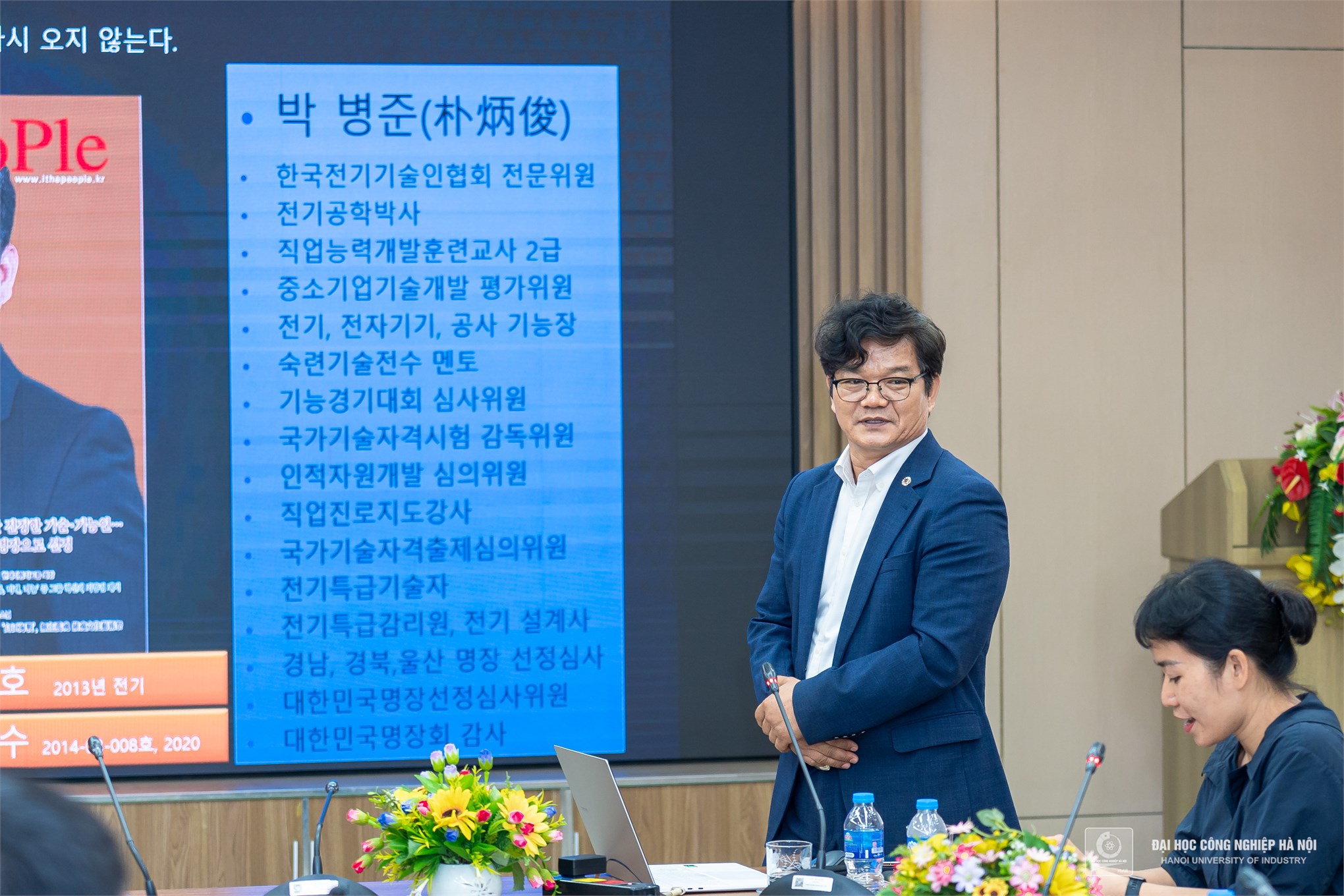

The seminar "Optimization in Design and Safety in Precision Mechanical Production: Experiences and Solutions" attracted a large number of staff, lecturers, trainees, and students

The seminar "Optimization in Design and Safety in Precision Mechanical Production: Experiences and Solutions," featuring two leading experts in mold manufacturing, offers a valuable opportunity for staff, lecturers, trainees, and students to exchange knowledge and insights. This platform allows participants to explore new directions in precision mechanical production that are closely linked to practical realities and ensure safety in manufacturing. Through this seminar, the faculty members gain new expertise in optimal plastic injection mold design, the application of specialized molds, and industrial-standard techniques for preventing electrical accidents. These insights will be updated, adjusted, and integrated into the curriculum to align with real-world practices and the evolving trends of the global manufacturing industry.

Mr. Won Yong-Gi, Vice President and Secretary General of the Korea Skilled Engineer Association, shared his experience on optimal design for plastic injection molds and the application of specialized molds.

Mr. Park ByeongJun, Director of the Park Byung Jun Electronics Research Institute, South Korea, introduced electrical safety inspection techniques and methods to prevent electrical accidents during production, ensuring the safety of workers and production systems.

A representative from the South Korean mold engineering expert group presented the Shool of Mechanical and Automotive Engineering with an Outside Micrometer set, valued at over 30 million VND

Mr. Won Yong-Gi, Vice President and Secretary General of the Korea Skilled Engineer Association, stated: “South Korea is currently one of the world's leading mold manufacturing nations, on par with industrial powerhouses such as Germany, Japan, the United States, and China. The rapid development of this industry has created a high demand for skilled, highly specialized young engineers in mold technology. The starting salary for a newly graduated mold engineer in South Korea can reach up to 1 billion VND per year.

This is an incredibly attractive figure, highlighting the wide career opportunities and high income potential that graduates in this field can achieve. We can confidently believe that the talent pool from the Faculty of Mechanical Engineering and Automotive Technology at HaUI is fully capable of integrating globally and meeting the stringent demands of the international labor market, especially in industrial giants like South Korea.