State-level research: Developing hot stamping mold manufacturing technology for automobile and motorcycle parts

That is the main content of the project "Research and technology transfer for designing and manufacturing hot stamping molds for automobile and motorcycle spare parts for enterprises in the field of supporting industries" conducted by Assoc.Prof.Dr.Pham Duc Cuong - Director of HaUI Institute of Technology, Hanoi University of Industry. At the Acceptance session of State-level scientific research topics in January 2022, the project was evaluated as a typical part of the Supporting Industry Development Program of the Ministry of Industry and Trade in 2021.

Strategy on development of Vietnam's automobile and motorcycle industry to 2025, with a vision to 2035 of the Government and Master plan on development of supporting industries to 2020, a vision to 2030 of the Ministry of Industry and Trade, mentioned "prioritizing the development of the field of components and spare parts to serve the needs of localization, especially the mechanical and automobile industries". Currently, the development of Vietnam's automobile - motorcycle industry and supporting industries are facing many difficulties and challenges in which there is a strong dependence on the mold industry.

On the basis of analyzing the actual situation at enterprises, the research team proposes to develop and implement the project "Research and technology transfer for designing and manufacturing hot stamping molds for automobile and motorcycle spare parts for enterprises in the field of supporting industries” with the purpose of using domestic intelligence and technology, gradually mastering hot stamping technology including design and manufacturing of molds and products, gradually replacing foreign imports, increasing the value of Vietnamese products in the supply chain of supporting industries.

Assoc.Prof.Dr.Pham Duc Cuong - Project Manager reported the research contents to the State-level Acceptance Council

The project includes 12 contents, including main tasks such as: Surveying and evaluating the market for hot stamping products; Designing, simulating, optimizing the digital hot stamping die design; Building technological process for manufacturing hot stamping dies using CAD/CAE software; Machining mold set; Testing and evaluating molds in actual production, perfecting the design; Training to transfer design technology and hot stamping products for enterprises to use and evaluate in production…

After 1 year of implementation, with the cooperation and support from a number of organizations and businesses, the project has completed the following main contents:

- Conducted market surveys and assessments on hot stamping products in the supporting industry, assessments on the capacity of designing and manufacturing hot stamping molds of a number of research units and mold manufacturing enterprises for the supporting industry in Vietnam. From the survey results, the project proposed a mold design process using the CAE simulation software tool.

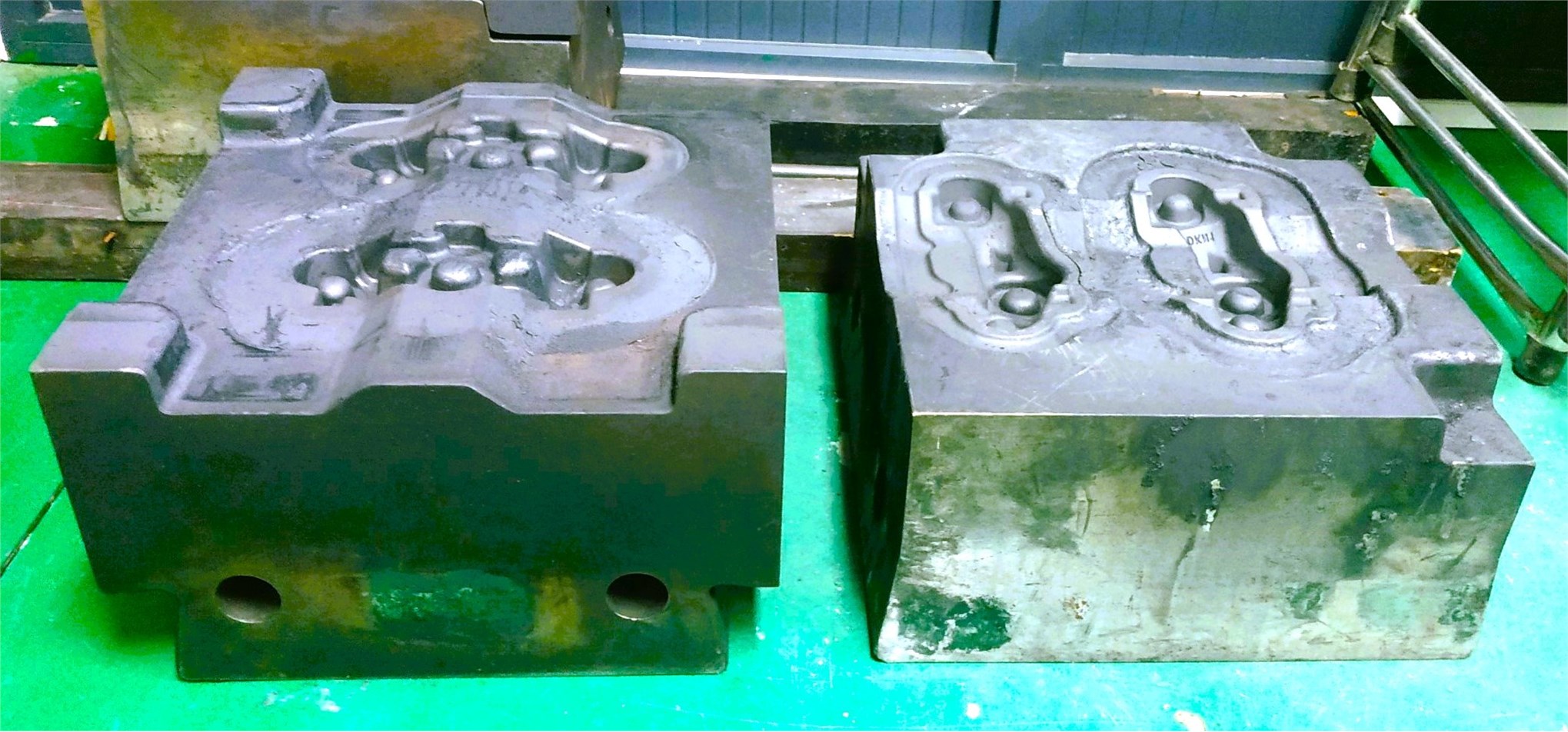

- Successfully implemented the design, simulation, and optimization of hot stamping mold design for 02 hot stamping molds to produce details such as steering wheels and connecting rods. Based on the results of simulation and analysis of mold structure, geometrical parameters of the workpiece were selected to ensure the working ability of the stamping machine, the filling capacity of the mold, and the heat requirements for different stamping steps and the quality of the product after stamping.

A set of stamping molds for steering wheels

- Successfully built 02 technological processes for manufacturing hot stamping molds using CAD/CAE software. The application of CAD/CAE/CAM technology allows the design of machining processes on modern CNC machining machines, ensuring accuracy, safety and efficiency for the production process.

- Successfully carried out the research and application of numerical simulation technology in mold calculation and optimization in order to improve and predict mold life. Based on 02 sets of molds that have been fabricated and tested, the process of simulation analysis, mold optimization has been performed to improve product quality and predict mold durability during hot stamping. The molds have been calibrated, the test results have resulted in higher quality products.

- Successfully implemented the training process to improve analysis, design, simulation and manufacturing of hot stamping molds with 06 courses for more than 60 participants. Simultaneously, the training content was carried out to transfer design technology and hot stamping products for 05 enterprises to use and evaluate during the production process, including 02 enterprises producing and manufacturing stamping molds.

The finished steering wheel and connecting rod products after cutting

With the results achieved, the project is highly appreciated when it is both scientifically meaningful and practical. In one year of implementation, there were many difficulties due to the prolonged COVID-19 pandemic, affecting more or less the process of implementing the project, the research team has tried to complete it correctly, sufficiently and somewhat exceeded the target compared to the original project requirements.